People talk about the industrial revolution as if it is something that happened in the past. But according to Bob Willoughby, president at Vancouver-based manufacturer US Digital, the industrial revolution is still going on, at a pace that rivals any other previous era – and US Digital is positioned to be right in the middle of a surge of new technology.

“We’re about to launch into a new phase that will change the way equipment is manufactured,” said Willoughby.

US Digital manufactures motion control devices called “optical encoders” as well as inclinometers. The encoders, attached to a motor, precisely control the motion of the part of the machine the motor is attached to. Encoder uses are varied and numerous, including surgical robots, the textile industry, airplanes, and even Coke machines and car seats.

Now, combine US Digital’s motion controllers with the latest in manufacturing technology – additive manufacturing – and you have a recipe for huge growth potential. Additive manufacturing is the industrial version of 3D printing. Instead of machining a piece of metal into what you need, additive manufacturing uses a sort of printer to lay down precise layers of a material (such as metal powder) to create a 3D part. According to Willoughby, General Electric is already using additive manufacturing to make aircraft engine parts, and an auto collector in California is manufacturing replacement parts for his classic cars.

These types of industrial printers require very precise motion control, which is good news for US Digital.

“Additive manufacturing is going to become pervasive, and our products are right in the middle of that,” Willoughby stated.

Willoughby also predicted “amazing changes” coming in the carpet and textile manufacturing industries, which would also use motion controllers and fuel US Digital’s growth.

As an example of that growth, the company is seeking to add four new positions to their existing 119 employees, and Willoughby said he expects that type of employment growth to continue. In 2013, the firm achieved an all-time monthly sales record – greater than any month since the company was founded by David Madore (currently serving as a Clark County Commissioner) in 1980.

“We were doing a celebratory luncheon every time we hit a monthly record,” said Willoughby, “but that has become so routine we’ve gone to quarterly luncheons.”

Last November, US Digital announced a new product that provides more accuracy than has been available in the past, and Willoughby said the company soon will be releasing another new product that provides a type of motion control that doesn’t exist today.

“We’re staying on top of what the marketplace needs, and staying ahead of that curve,” said Willoughby. He added that the company recently achieved ISO 9000 certification, and is considering applying for International Traffic and Arms Regulations (ITAR) registration, which would enable them to sell customized products for military use.

Willoughby credits US Digital’s success to the company’s vertical integration. According to Willoughby, the firm subcontracts “hardly anything,” performing all their own design engineering, manufacturing and testing at their 118,000-square-foot facility in Vancouver. Doing everything in-house, said Willoughby, enables the company to be sensitive to customers’ needs and design custom solutions when necessary.

“Customers in the robotics and medical area need precise motion, and we can make encoders that do specifically what they want,” said Willoughby.

By partnering with customers and contributing to their success, he continued, US Digital ensures its own success.

The company’s environmental stewardship program, which includes recycling “virtually everything,” and their unique outreach center, which houses 38 Christian-centered ministries that serve local and global needs, are other examples of how US Digital’s corporate philosophy reaches beyond their own bottom line. The outreach center occupies 17,000 square feet of space at the facility.

“We provide them with space, a phone system – everything they need so they can afford to provide their services,” said Willoughby.

As US Digital prepares for growth, Willoughby said, space may become problematic.

“I’m looking at where we are going to put all the equipment in the next three years,” said Willoughby, explaining that they are buying equipment that they don’t need right now, but will need in the future. He does not expect to move the entire facility, but the firm may add a satellite site “probably here in Vancouver.”

US Digital receives award from Microsoft

This week, Microsoft awarded Vancouver-based US Digital with the “Dynamic Business” 2014 Customer Excellence Award. The award was presented at the Microsoft Convergence Convention in Atlanta on March 5.

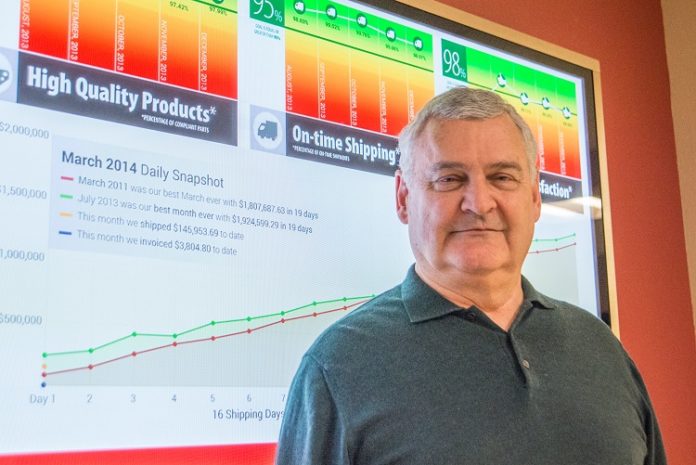

Bob Willoughby, US Digital president, said the award was based on the company’s lightning-quick deployment of Microsoft’s enterprise resource planning product, Dynamics GP. Not only did US Digital deploy the system in record time, but also worked with seven other vendors to integrate their software systems into the ERP system.

“This was important to Microsoft because we are a manufacturing company with all aspects of our operations running through GP with exemplary results,” said Willoughby.

In fact, the Microsoft partner that works with US Digital recently wrote a book on rapid implementation and integration, based on US Digital’s experience and methodology.