From handheld apps to 3-D maps, high-tech innovations are changing how today’s construction firms get the job done.

From handheld apps to 3-D maps, high-tech innovations are changing how today’s construction firms get the job done.

Just ask Matthew Braun, project executive with Howard S. Wright, one of the Northwest’s largest contractors. Braun is on Wright’s Capability Center team, which is charged with identifying emerging trends and tools for the rest of the company to adopt.

“We’re not trying to find out what’s cool, we’re looking for tools that will eliminate waste and benefit our clients,” he says.

Or ask Tracy Roundy, who co-owns Priority Contractor LLC in Vancouver, and is part owner of an app aimed at helping contractors. “For a small company to stay profitable, a tool like this can be essential.”

Or ask Tim Schauer, president and CEO of MacKay Sposito, which consults on energy, public works and land development projects. “The right tool can be a game-changer,” he says.

So what are these innovations? We asked these leaders of companies large and small to weigh in on changes to the tools they use – and to tell us how new innovations are reinventing the way that they do business.

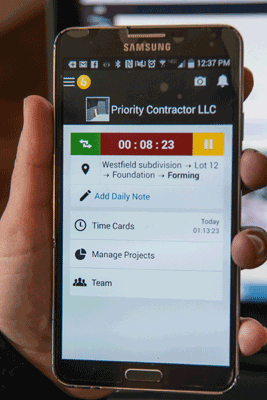

At Priority Contractor, an app called BusyBody excited Roundy and her husband, Melvin, so much that they became part-owners.

With BusyBody, employees can clock in and clock out digitally from a work site. That remote time-card alone is saving the company money, Roundy said, because when workers fudge their paper time-cards by small amounts that add up fast. It also tracks where an employee was when he or she clocked in, allowing the company to monitor employees without keeping an in-person watch.

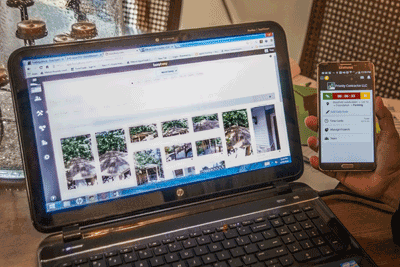

Perhaps just as significant, the app also tracks progress on construction projects. An employee working on several different jobs can track how much time was spent on each, and can take photos that document progress along the way.

Perhaps just as significant, the app also tracks progress on construction projects. An employee working on several different jobs can track how much time was spent on each, and can take photos that document progress along the way.

“We subcontract all of our electrical work, so I make all of my guys take pictures before they put up drywall,” Roundy says. “That way we have documentation that the work was done.”

“A time-card app is a significant innovation,” Braun, at Howard S. Wright, said when told about BusyBody. Braun is on the lookout for technology that cuts down on paperwork and automates time-consuming processes.

A big money-saver for his firm is what Howard S. Wright calls its “Smart Box” – essentially a well-built toolbox with a wireless Internet-enabled laptop inside.

“Now instead of giving subcontractors a 2-D image on a piece of paper, we can give them the big picture through the computer,” Braun says. If the plans for a major project change, the Smart Box gets the update wirelessly – there’s no need to print out new documents.

Howard S. Wright also uses iPads and laptops to display images of its blueprints. Buying dozens of tablets might sound like an odd way to save money, but the cost of printing new blueprints adds up quickly.

“On a $140 million project, $250,000 could be printing costs,” Braun says. “Reading from computers or tablets drives waste out.”

Innovation efforts at Howard S. Wright are focused heavily on eliminating waste and making informed decisions.

New estimating tools, for example, allow clients to understand exactly how each decision will affect energy use down the line. And three-dimensional models allow the company to understand the physical space it uses.

Those 3-D tools – known as BIM, for building information management – have been a game-changer at MacKay Sposito, as well, Schauer says.

“We had to put a new turbine into a dam last month,” he says. “We were able to scan the entire dam to get an exact measurement of its dimensions.”

Mapping with BIM tools is faster than measuring space by hand, and often more accurate, and the technology continues to evolve. Schauer says that he anticipates a time when digital scanners can be mounted on aerial drones and used to develop 3-D maps of landscapes from above.

As mapping tools help MacKay Sposito get a big view of what’s happening on the job, another digital innovation allows the company to manage its multi-state fleet of vehicles.

“Our employees are stretched out across six states,” Schauer says. “So we’ve started using a system to track them.”

The company has placed a GPS unit in each truck, and gives employees authorized to drive the vehicles a key fob. The fob lets the company know which worker is driving at any given time. And the GPS can tell how well that person is driving – and even send automated messages telling the driver to slow down if he or she is going too fast.

The result seems to be safer drivers: Last year MacKay Sposito’s fleet drove more than 500,000 miles without a major accident.

“When employees know they’re being tracked, there’s a cultural adaptation that happens,” Schauer says. “They change their behavior.”

Roundy says the tracking app that Priority Contractor uses doesn’t just remind employees to be on their best behavior – it allows the company to reward people for good results.

“If you have two guys on different job sites who are doing the same thing, and one finishes three hours sooner than the other, you know who is working harder,” she says. Her company identified one project manager who consistently outperformed his peers. “He now drives the company truck and we pay for his phone, because we wanted to reward him for performing so well.”